Company Overview

AVEX-SG primarily specializes in professional integration planning and design of in-house electrical and control software and hardware. Additionally, we provide expertise in on-site hardware planning, construction, and testing.

AVEX-SG's complete organizational structure and well-equipped facilities have earned recognition and praise from domestic and international clients. We have established partnerships with numerous overseas major manufacturers, also with the clients from Europe, the United States, and Japan.

We have obtained various certifications, including international ISO9001:2015, China's low-voltage equipment CCC, US UL508A, ISO13485:2016, and GMP.

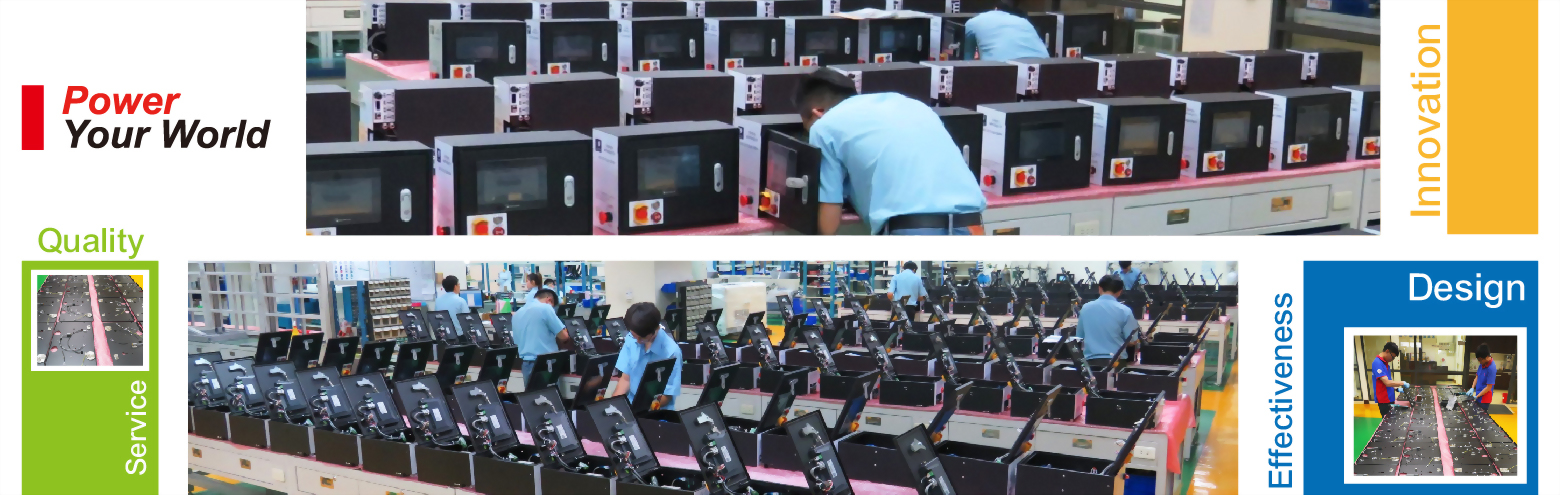

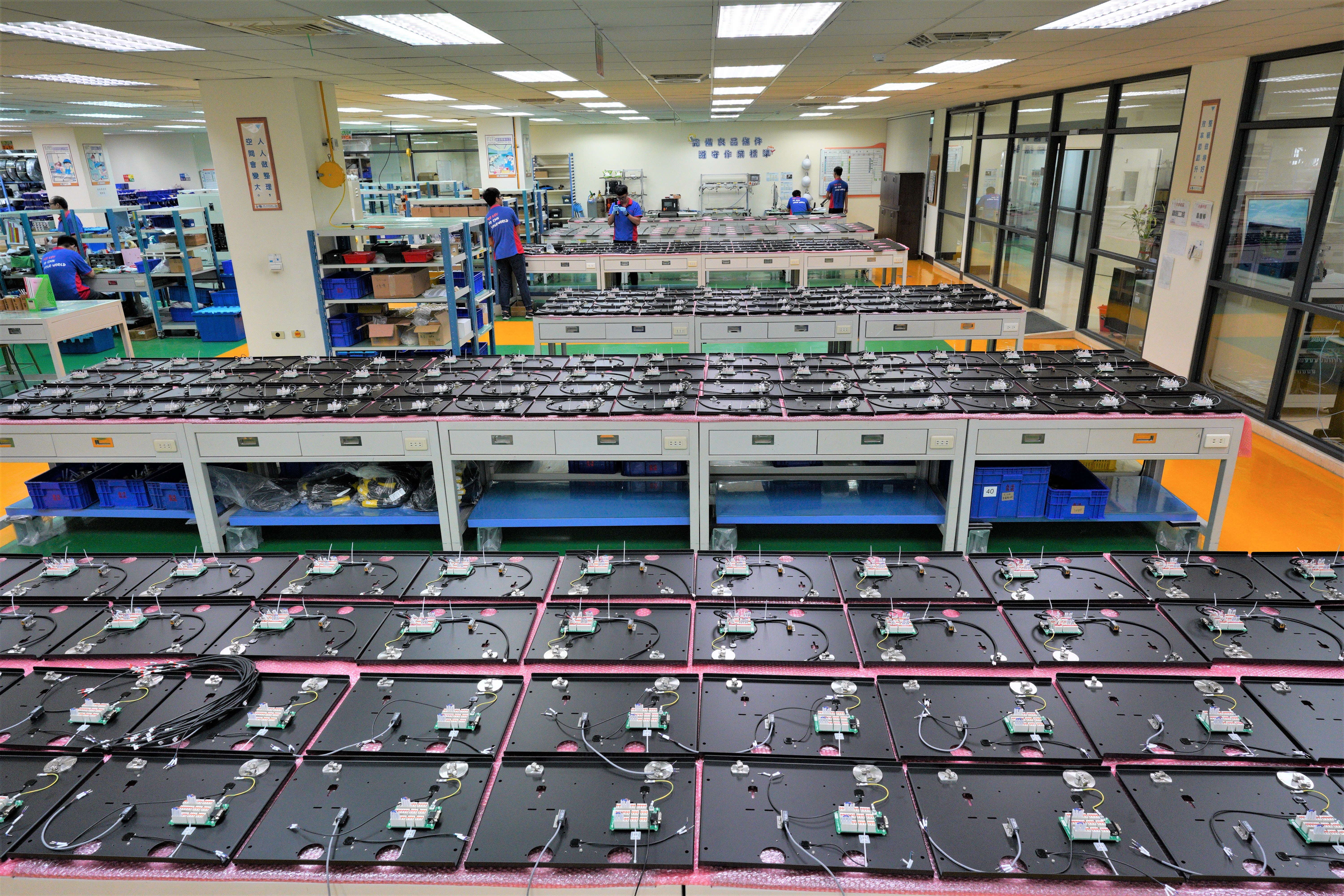

Specializing in the standardization of mass-produced electrical units including circuit planning, design, and execution. Through a gradual modular configuration approach, it's the only way for time, labor, and cost-saving. It also achieves a high level of commonality, stability in quality, and convenience in pre-sales and after-sales services.

The standardization within Mechatronics dept. focuses on the establishment, issuance, and implementation of standards. Therefore, as long as electrical units can go on mass production progress, we are profession for help customers in producing to meet international standards and production requirements.

In recent years, we have expanded into the field of semiconductor electronic equipment, providing corresponding electrical control systems and data acquisition control functions for equipment and machinery. Based on customer requirements, we take the design concept of standardization modules to optimize products, aiming to achieve the goal of mass production.

In terms of electrical control, we aim for vertical integration and modularization of electrical units based on the department's professional planning capabilities. We have technical expertise in system integration with upper-level programs and in the application of loop control to lower-level components. By integrating electrical control units into mechanical designs, we can achieve a higher degree of automation.

About the equipment mechanisms and sensor components, we adopt the synergistic approach to get the synergism effect. We collaborate with our business units, leveraging specialized divisions to conduct requirement planning, selection, and optimization. This kind of cooperation makes this aspect more flexible and precise in responding to different job requirements. It transforms the mechanical component assembly into an intelligent, controllable system, and also be efficient to meet specific customer needs while enhancing overall system performance and reliability.