IOT Example

![]() Program

Program

|

|

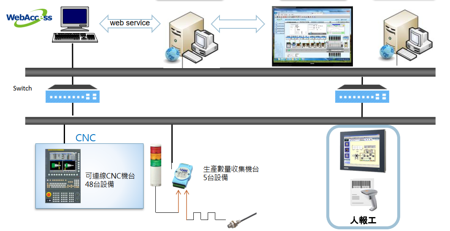

- CNC Visualization Solution - AVEX-SG offers a CNC visualization solution aimed at assisting machine tool users in upgrading their equipment and addressing the critical networking challenges in the machine tool industry. This solution contributes to the realization of factory intelligence by leveraging the power of connectivity and visualization. By collaborating with Advantech's WebAccess/CNC or FANUC MT-LINK I software, we provide a comprehensive visualization product solution. This empowers machine tool operators with real-time production information and visualization capabilities, facilitating their transition towards the goals of Industry 4.0. This solution not only enhances the efficiency and monitoring of machine tool operations but also supports the integration of smart manufacturing practices and data-driven decision-making within the manufacturing process. |

|

|

|

|

|

|

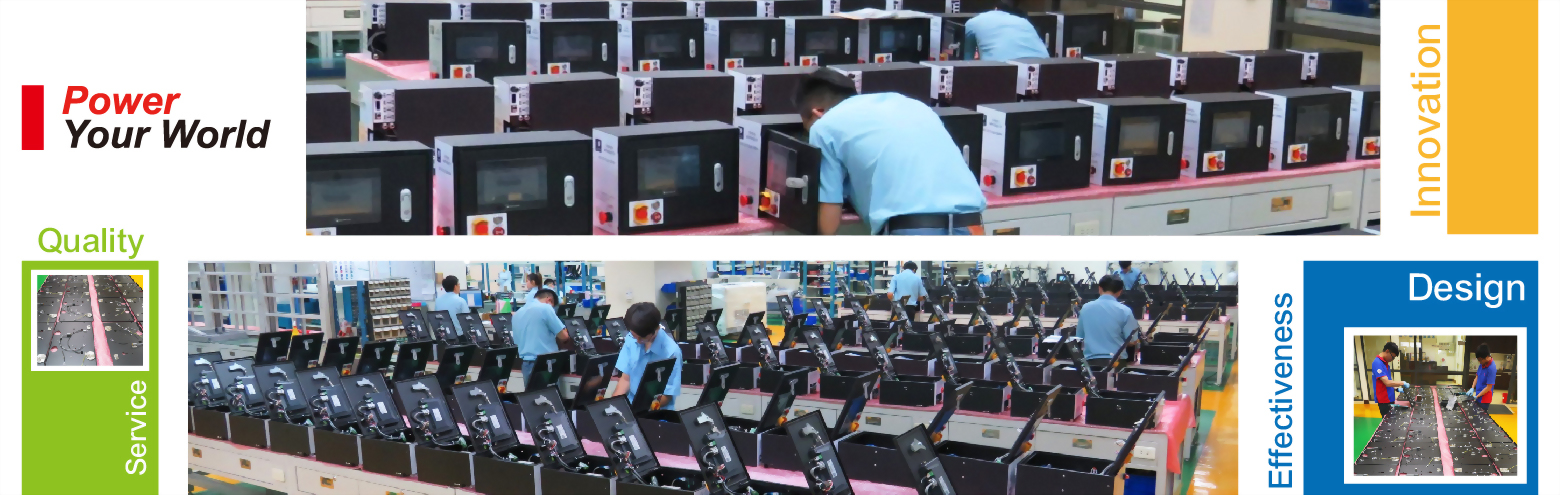

- OEE Line Equipment Utilization Solution - Leveraging Advantech's Smart Factory solution for the optimization of Overall Equipment Effectiveness (OEE) in a metal hand tool manufacturing facility. This solution involves the integration of intelligent factory components and system development.We have established a comprehensive OEE platform for the factory, enabling the collection of production information from various machinery on the production line. Through computational analysis and consolidation, this data is transformed into a comprehensive overview of machinery utilization rates. The data is presented in graphical form on the central computer screens in the control room. This provides managers with real-time insights and historical data, facilitating data-driven decision-making and performance optimization. |

|

|

|

|

|

|

- Wafer Box IoT Monitoring System - Our solution utilizes the Azbil Smart IoT Gateway (NX-SVG) to connect a large number of Azbil MFC (Mass Flow Controller) flow meters. This setup enables the transmission of MODBUS RTU data through the Gateway to a PLC. Leveraging the flexibility and user-friendly configurability of the NX-SVG, the solution can be rapidly deployed within semiconductor equipment.Apart from data collection and recipe applications, the system can also integrate AI software for machine learning and other advanced applications. This enhances both the system's stability and the refinement of manufacturing processes. The IoT monitoring system not only gathers valuable data from various points within the semiconductor production process but also utilizes AI capabilities to optimize operational efficiency, contributing to the overall enhancement of production quality and yield. |

|

|

|

|

|

|

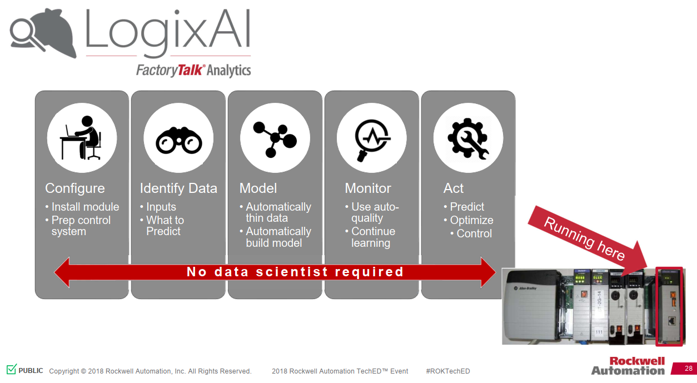

- Industrial Machinery AI Machine Learning Solution - |